Manufacturer’s Spotlight: Electrolytic Technologies

Share in:

Share in:

Using brine-to-bleach technology and commissioned under the trade name Klorigen™, QSM represents Electrolytic Technologies to bring you on-site chlorine and sodium hypochlorite generation.

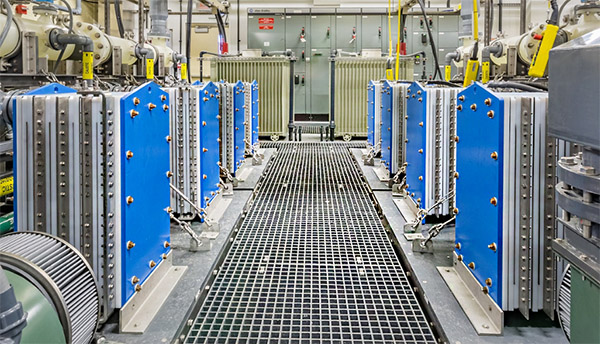

Read below to learn more about Electrolytic Technologies and Klorigen™.The technology is used primarily in municipal facilities and at chemical/industrial plants, and it provides customers with high quality solutions for water and wastewater disinfection. Klorigen™ systems utilize membrane-cell electrolysis technology to safely produce chlorine gas and/or NSF ANSI Std. 60 compliant sodium hypochlorite.

Every system is custom designed to meet the user’s specific needs. Modular design allows for ease of expansion with minimal interruption to operations and increase to the total system footprint, allowing users to plan for future increases to their disinfection requirements. Klorigen™ Systems contain a minimal amount of chlorine at any given time (approx. 1-2 pounds per 2,500 lbs/day generation capacity) and operate under vacuum to effectively eliminate chlorine and its hazards from site. Hydrogen produced in the electrolyzers is diluted with air as it is generated to well below the LEL and safely vented to atmosphere.

Generated chlorine can be safely injected to the user’s disinfection water stream on-demand as it is generated to safely maintain gas disinfection, or it can be combined in the process with co-product sodium hydroxide to produce a high-quality sodium hypochlorite product at up to 15% concentration, typically at costs well below that of commercially available product. In addition, Klorigen™ systems can feature a “hybrid” design in which chlorine, sodium hydroxide AND sodium hypochlorite are all generated simultaneously.

Electrolytic Technologies has extensive experience installing and implementing On-site Sodium Hypochlorite Generation Plants across the globe. The company has supplied fully engineered, factory-tested, and ready-for-installation plants since 2001.

QSM is the exclusive distributor for Electrolytic Technologies in Mississippi and in the Florida Panhandle. Call QSM for your water and wastewater treatment needs.

Klorigen’s technology is typically used in water and wastewater treatment, pulp and paper manufacturing, mining and power generation.

QSM serves municipal systems primarily, and partnership with Electrolytic Technologies brings you the best in disinfection applications.

Traditionally, water utilities have used chlorine gas as the disinfectant of choice in their water treatment plants. However, recent publicly reported chlorine leakages and other threats have raised concern regarding the safety of this practice.

—–

Although some public utilities are evaluating alternative technologies to pressurized chlorine gas, chlorine remains the most effective broadband disinfectant.

In response to this preference, Klorigen™ on-site chlorine gas generators can facilitate the continuation of current disinfection methods while promoting safe practices through the use of chlorine gas at ambient pressure.

Alternatively, water disinfection may be safely and effectively accomplished using Klorigen™ on-site generation of high strength sodium hypochlorite solution. Storage of 12.5% concentration requires less than one-fifteenth of that needed for low strength (i.e. less than 0.8%) generated sodium hypochlorite.

Klorigen™ systems are ideally suited for wash disinfection. The generated bleach is chemically ultra-pure and produced at a consistent quality and concentration, unlike commercial bulk deliveries which often undergo degradation between production and use.

Using primarily salt, water, and electricity, Klorigen™ generators produce non-pressurized chlorine gas, membrane-grade sodium hydroxide, and 10-15% high strength sodium hypochlorite at the point-of-use.

Installing on-site chlorine generation systems typically results in lower costs, reduced risk, and fewer disinfection byproducts when compared to pressurized chlorine gas or bulk sodium hypochlorite. In short, it’s safe!

Traditional usage of chlorine gas for disinfection raises many concerns, such as high shipping and insurance costs, risks of an accident, and the overall risk associated with transporting, storing and handling pressurized chlorine gas.

In addition to these concerns, standard methods of storing pressurized chlorine gas on-site require that users maintain a U.S. EPA-required Risk Management Plan (RMP) and undergo HAZMAT training. Klorigen™ systems typically eliminate or greatly reduce these requirements.

These requirements have motivated some plant owners to explore procurement alternatives such as on-site chlorine gas or transition to the use of sodium hypochlorite (NaOCL) as a disinfectant.

Klorigen™ on-site chlorine generation allows water treatment plants to become independent, eliminating their reliance on third party chemical suppliers, , whether the disinfection requirement is chlorine gas or sodium hypochlorite.

For plants that have opted to maintain chlorine gas as the disinfectant of choice, strict regulations coupled with logistical challenges and safety concerns are driving forces for an on-site solution. Klorigen™ allows these users to maintain their preferred method of gas disinfection while effectively eliminating pressurized chlorine from site.

The initial upfront investment in equipment is often offset by the lower cost of production over time. Additionally, sodium hydroxide (NaOH, or caustic soda) is produced in the on-site chlorine gas generation process as a co-product, providing a substantial cost-benefit. For users of sodium hydroxide, this “caustic credit” can significantly defray from their chlorine production costs.

Unlike pressurized chlorine gas, chlorine generated by a Klorigen™ on-site chlorine generation system is produced on demand at atmospheric pressure. Chlorine generated in this method is injected directly into the plant water feed for disinfection as it is produced; eliminating the need for transportation, storage, and handling of chlorine gas on site.

For every 2,500 pounds (1,200 kgs) of daily chlorine generation capacity, no more than 1-2 pounds (.5-1 kg) of chlorine gas is present in the system, under vacuum. Hydrogen generated in the electrolyzers is diluted to less than 2% of the LEL (Lower Explosive Limit) as it is produced and safely vented to the atmosphere.

KlorigenTM also is certified as a Qualified anti-terrorism technology by the United States Department of Homeland Security (DHS) due to its inherent safety features.

Transportation, storage, and handling of pressurized chlorine gas are eliminated, alleviating safety concerns accompanying its use. Furthermore, many fail-safes and redundancies are built into the system to ensure safety for the plant and its operators.

If you are a chlorine user who would like to maintain chlorine gas as your disinfectant of choice but often find yourself occupied by safety and usage concerns, or if you are a user of sodium hypochlorite interested in reducing costs and logistical inefficiencies, a Klorigen™ on-site generator may be the solution that you have been searching for.

To learn more about how your plant can benefit from Klorigen™ on-site generation technology, please contact TJ Truxillo, QSM’s VP, Environmental to learn more. Call 855-469-2015.