QSM Signs Distributorship Agreements with Proco & Electrolytic Technologies

Share in:

Share in:

QSM — a regional leader in sales and service for the process equipment industry — has signed two new agreements with original equipment manufacturers.

With agreements now in place, QSM adds Electrolytic Technologies and Proco to its line card of solutions for the water treatment and wastewater treatment industry.

QSM will serve as Master Agent for Proco in Louisiana, Mississippi, Alabama, and the Florida panhandle. With Electrolytic Technologies … QSM will serve as exclusive sales rep in Mississippi and in the Florida panhandle.Both of these companies have strong engineering and manufacturing capabilities, and — at a local level — QSM brings knowledge and resources needed to satisfy the diverse requirements of individual process plants in the southeast region.

Electrolytic Technologies and Proco benefit from QSM’s ability to provide long-term vision, stability, and single source capability to end-use customers, that fit the strategic goals of each product line.

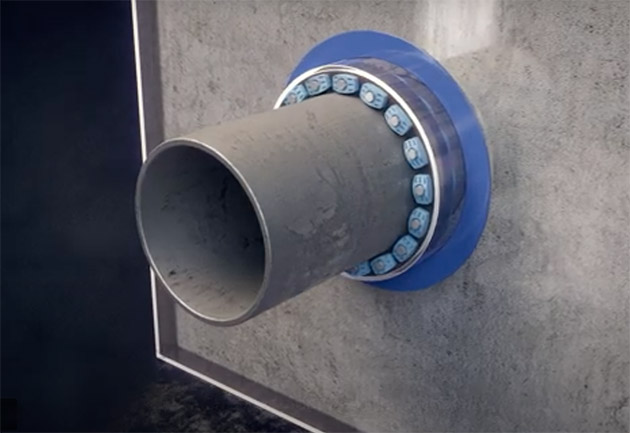

Proco Products: is a global leader in the design and supply of expansion joints for piping and ducting systems. For more than 30 years, Proco has prided itself on offering the most complete line of products to suit a wide variety of applications — including rubber and molded PTFE expansion joints, braided flexible hose assemblies, low torque sealing gaskets, and Pen Seal (Pipe Penetration Seals).

Proco Products: is a global leader in the design and supply of expansion joints for piping and ducting systems. For more than 30 years, Proco has prided itself on offering the most complete line of products to suit a wide variety of applications — including rubber and molded PTFE expansion joints, braided flexible hose assemblies, low torque sealing gaskets, and Pen Seal (Pipe Penetration Seals).

Chief among Proco’s product are the Series 700 ProFlex™ rubber duckbill check valves. These valves are commonly used in the water and sewage industry, and also can be used in drainage and stormwater management applications,

Call QSM to learn more about ProFlex™ check valves, and more.

Electrolytic Technologies: manufacturers and installs on-site sodium Hypochlorite generation plants using brine-to-bleach technology commissioned under the trade name Klorigen™. These plants are fully engineers, factory-tested, and ready-for-installation.

This technology is used in water and wastewater treatment, pulp and paper  manufacturing, and at power generation facilities.

manufacturing, and at power generation facilities.

In the Klorigen™ process, chlorine and / or sodium hypochlorite is produced from salt, water, and electricity. It is then delivered at the point of usage, on-demand, to provide fresh product when required. These disinfectants are safely generated under vacuum, which eliminates the threat of toxic gas release. All systems are delivered fully assembled, and ready for installation.

Electrolytic Technologies products have a reputation for being low maintenance, and in most instances Klorigen™ generated bleach is considerable less expensive than purchased commercial bulk product.

Call QSM to learn more about Klorigen™, and its application at your plant or treatment facility.

Contact: TJ Truxillo. 855-469-2015 and tj@theQSMgroup.com

Both of these companies have strong engineering and manufacturing capabilities, and — at a local level — QSM brings knowledge and resources needed to satisfy the diverse requirements of individual process plants in the southeast region.

Electrolytic Technologies and Proco benefit from QSM’s ability to provide long-term vision, stability, and single source capability to end-use customers, that fit the strategic goals of each product line.